Pre-laying and Installation

Final Testing

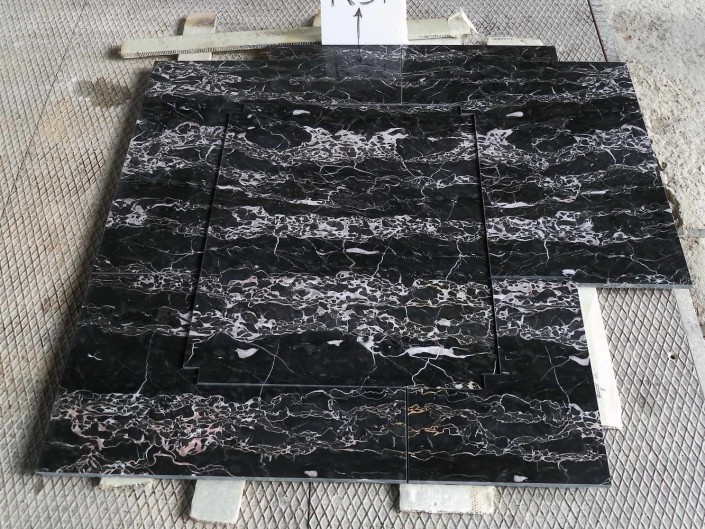

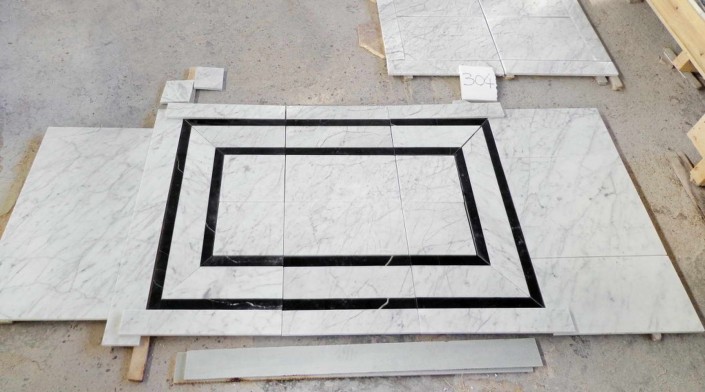

Once all the production phases have been completed, each project is pre-assembled and completely dry laid in our workshop facility. All the component parts are placed side by side according to a predetermined pattern, in order to verify that the design works and is book-matched to perfection, make sure the colour quality and aesthetics of the combinations are fully rendered and that each individual element making up the three-dimensional whole fits perfectly. The testing takes place in the presence of the Project Designer and the Client who supervise the finished work to ensure quality of workmanship and compliance to the original project. This carefully executed service provides the Client with an additional guarantee as to the quality of the final product.

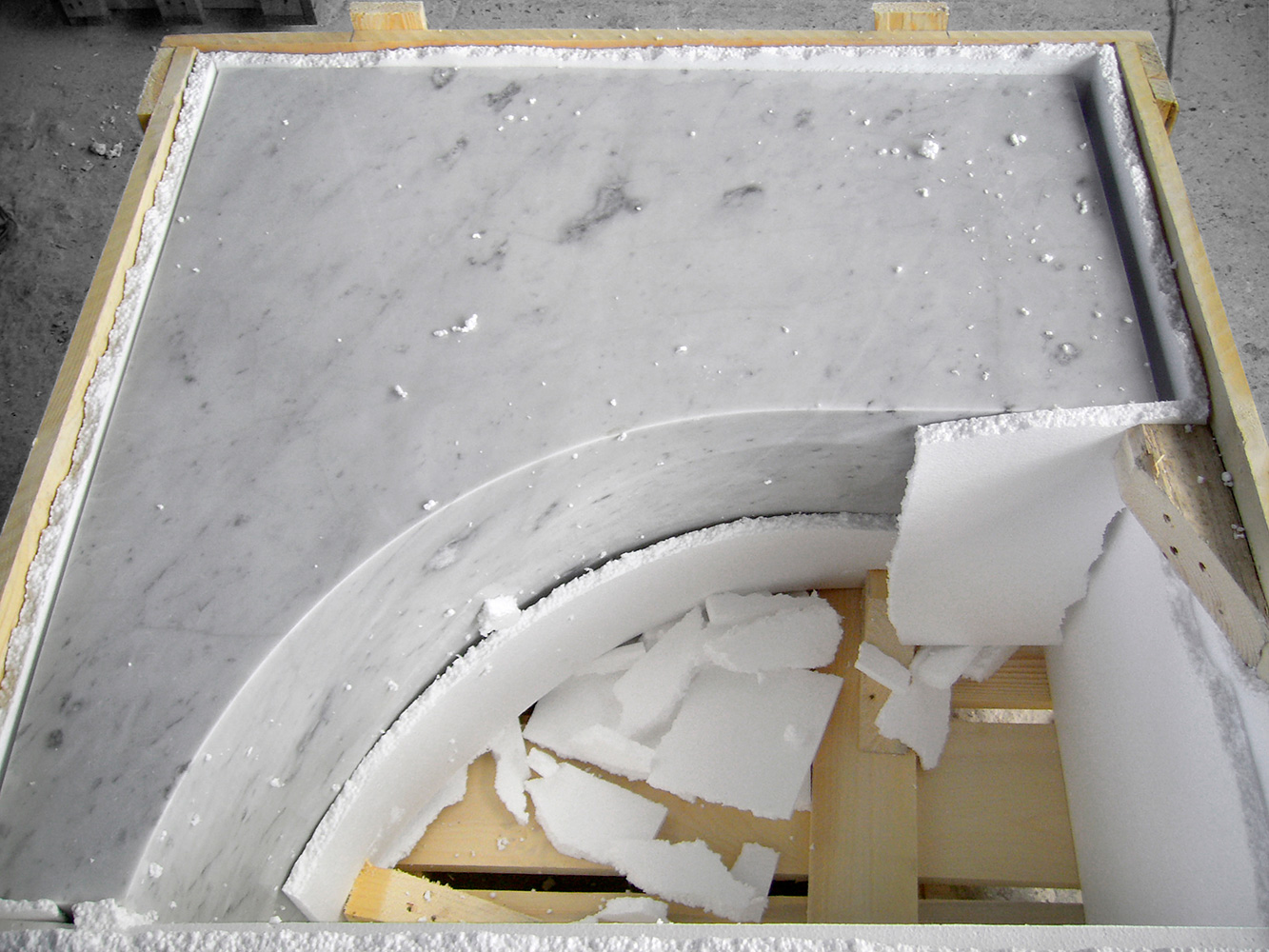

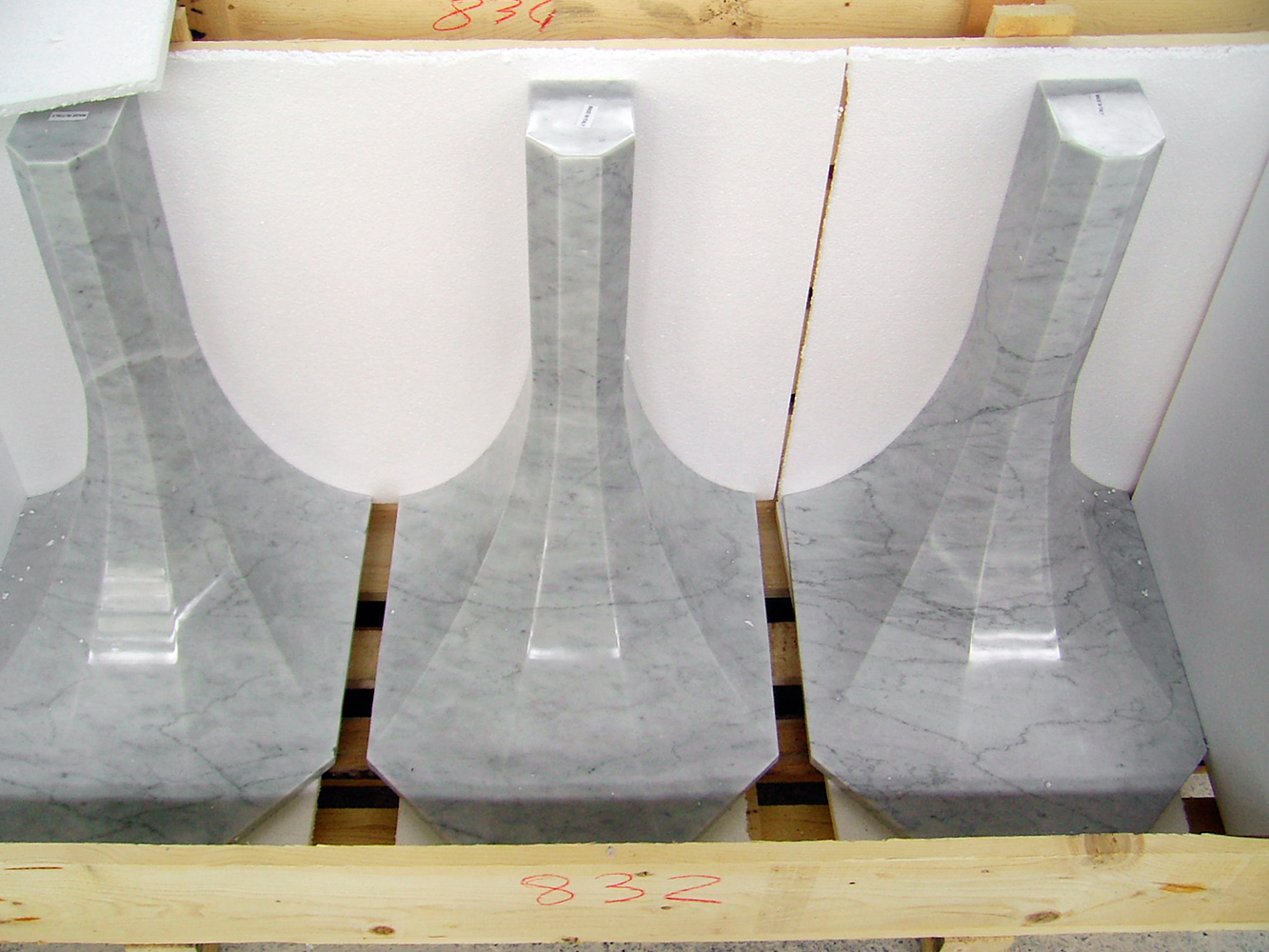

When pre-assembly and testing has been completed, the material is carefully packed in protective wooden crates, specially made for long-distance transport. Each item is numbered and, thanks to drawings supplied by us, assembly operatives will find the final installation process much easier, quicker and error-free. After packing, the project manager will have the crates loaded for shipment.

Installation is a delicate process and is carried out all over the world by specialized workers and technicians, partners of our company and experts in assembling marble and stone products. After supervising the opening of the crates containing all the parts, the technical team can proceed with the final installation of the entire project. Each phase of the installation process undergoes careful and thorough inspection by one of our staff, to ensure that all parts are laid to match the original project.