Working Marble

Cutting-edge Facilities

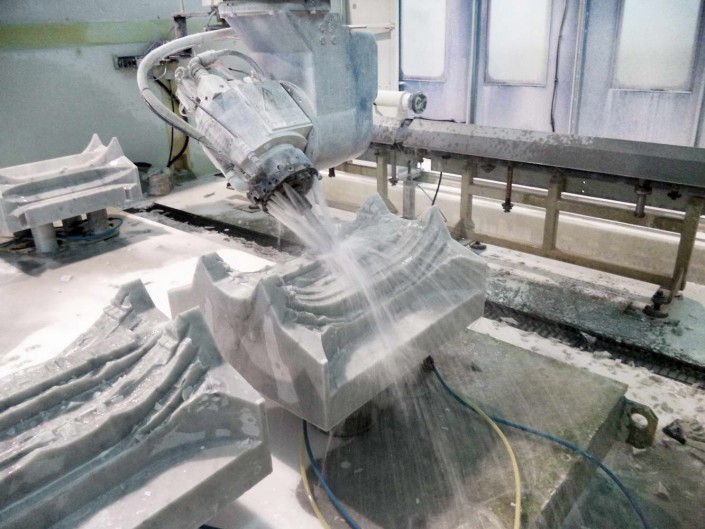

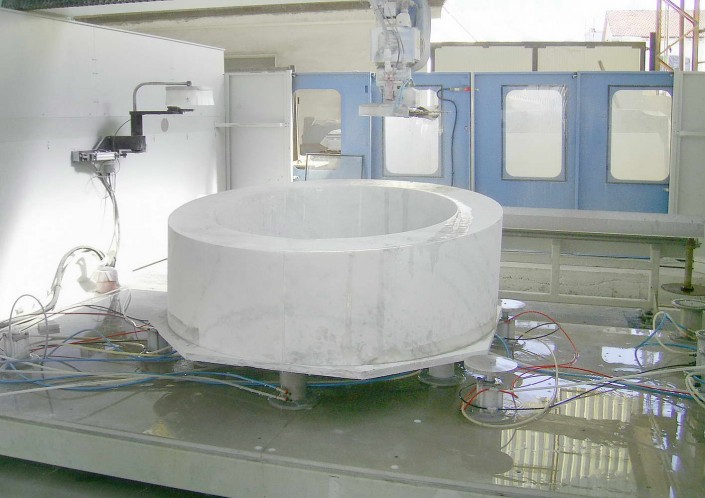

Our workshop facility is fitted with the most advanced machinery for the automated processing of all types of stone. Our machinery is constantly monitored and updated and includes various CNC machines such as bridge saws, 3 and 5 axis interpolated contouring machines, a large waterjet cutting system, as well as edge polishers, slab polishers and manual polishing machines. This innovative machinery allows us to achieve high levels of productivity, provide quality with the utmost attention to detail, and produce any type of three-dimensional object setting no limits on creativity. Finishing is rigorously carried out by hand using the tried and trusted techniques of an age-old craftsmanship that is part of our DNA, perfectly integrated into the daily workflow in a harmonious mix of tradition and innovation.

We carry out many types of processing:

Flooring with decorative features, book-matching and medallions; flooring with artistic inlay work (waterjet); Interior and exterior wall cladding for private residences and large architectural, public and commercial buildings and complexes; Basins, bathtubs, counters and other architectural, design features in solid stone; Fireplaces, Columns, Capitals, Statues, Ornamental Fountains, Stairs, Urban Design; Vanity tops, Kitchen countertops, Shower Trays; etc; Any type of stone can be combined with different materials such as steel, metal, wood, glass, corian, etc .

Workshop Facility Equipment

Keeping abreast of technology and innovation is the strategic, constant requirement that makes Cooperativa Marble + a highly competitive company and an ideal partner for the realization of projects in marble and stone of any type or size. Our workshop facility is equipped with advanced CNC machinery, allowing extremely high-level precision work, as well as quality and speed at competitive costs. Our equipment includes two new, versatile Brembana Maxima and Speed MB machining centers, with 3 and 5 interpolated axes, designed to work slabs and blocks of stone and composite stone (including greater thicknesses) with speed and accuracy. The two machine centers can perform any type of edge contouring, surface processing (rough or polished), milling, drilling, countersinking, pocketing, emptying, bas-reliefs and writing. Their large-sized, pre-drilled Duralumin work tables guarantee an absolutely flat work area for consistently flawless results, and the possibility of working several pieces with one single positioning. They have the capability of operating with diamond discs up to 500 mm in diameter for cutting and shaping, and cup wheels for forming and polishing convex shaped profiles. Up to 52 tools for linear, automatic or rotary tool changes, allow a wide range of processing operations to be carried out, without having to retool the machine. A control system checks tool wear automatically adjusting tool position, horizontally or vertically, to ensure a high quality finish.

Two CNC bridge saw milling machines

jib saw

manual polishing machine

slab polisher

edge polisher

3-axis contouring machine

Contouring machine with 5 interpolated axes

Waterjet cutting system

CMS BREMBANA MAXIMA

5/6 interpolated Axis Machining Centre

CMS BREMBANA SPEED MB

5/6 interpolated Axis Machining Centre